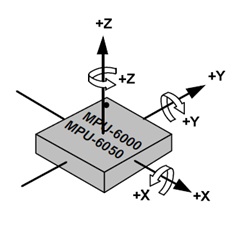

04 Sensor Calibration

一、陀螺仪校准方案

/**

* Adds a new value to the variance buffer and if it is full

* replaces the oldest one. Thus a circular buffer.

*/

static void sensorsAddBiasValue(BiasObj* bias, int16_t x, int16_t y, int16_t z)

{

bias->bufHead->x = x;

bias->bufHead->y = y;

bias->bufHead->z = z;

bias->bufHead++;

if (bias->bufHead >= &bias->buffer[SENSORS_NBR_OF_BIAS_SAMPLES])

{

bias->bufHead = bias->buffer;

bias->isBufferFilled = true;

}

}

/**

* Checks if the variances is below the predefined thresholds.

* The bias value should have been added before calling this.

* @param bias The bias object

*/

static bool sensorsFindBiasValue(BiasObj* bias)

{

static int32_t varianceSampleTime;

bool foundBias = false;

if (bias->isBufferFilled)

{

sensorsCalculateVarianceAndMean(bias, &bias->variance, &bias->mean);

if (bias->variance.x < GYRO_VARIANCE_THRESHOLD_X &&

bias->variance.y < GYRO_VARIANCE_THRESHOLD_Y &&

bias->variance.z < GYRO_VARIANCE_THRESHOLD_Z &&

(varianceSampleTime + GYRO_MIN_BIAS_TIMEOUT_MS < xTaskGetTickCount()))

{

varianceSampleTime = xTaskGetTickCount();

bias->bias.x = bias->mean.x;

bias->bias.y = bias->mean.y;

bias->bias.z = bias->mean.z;

foundBias = true;

bias->isBiasValueFound = true;

}

}

return foundBias;

}二、加速度计校准方案

1. 重力加速度校准

2. 水平校准

三、激光传感器校准方案

最后更新于